Saglietti Group was born in Narzole, a small town in the district of Cuneo in the core of the Langhe’s area at the end of 1800s.

The company changes across four generations by finding a new identity and creating new departments.

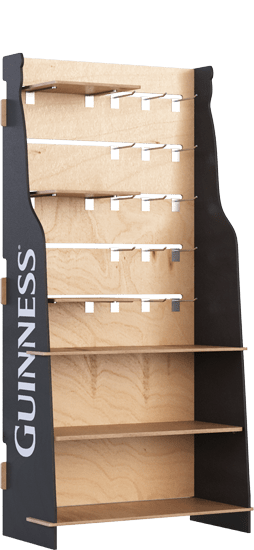

Saglietti Group launched a new brand: Esposit.

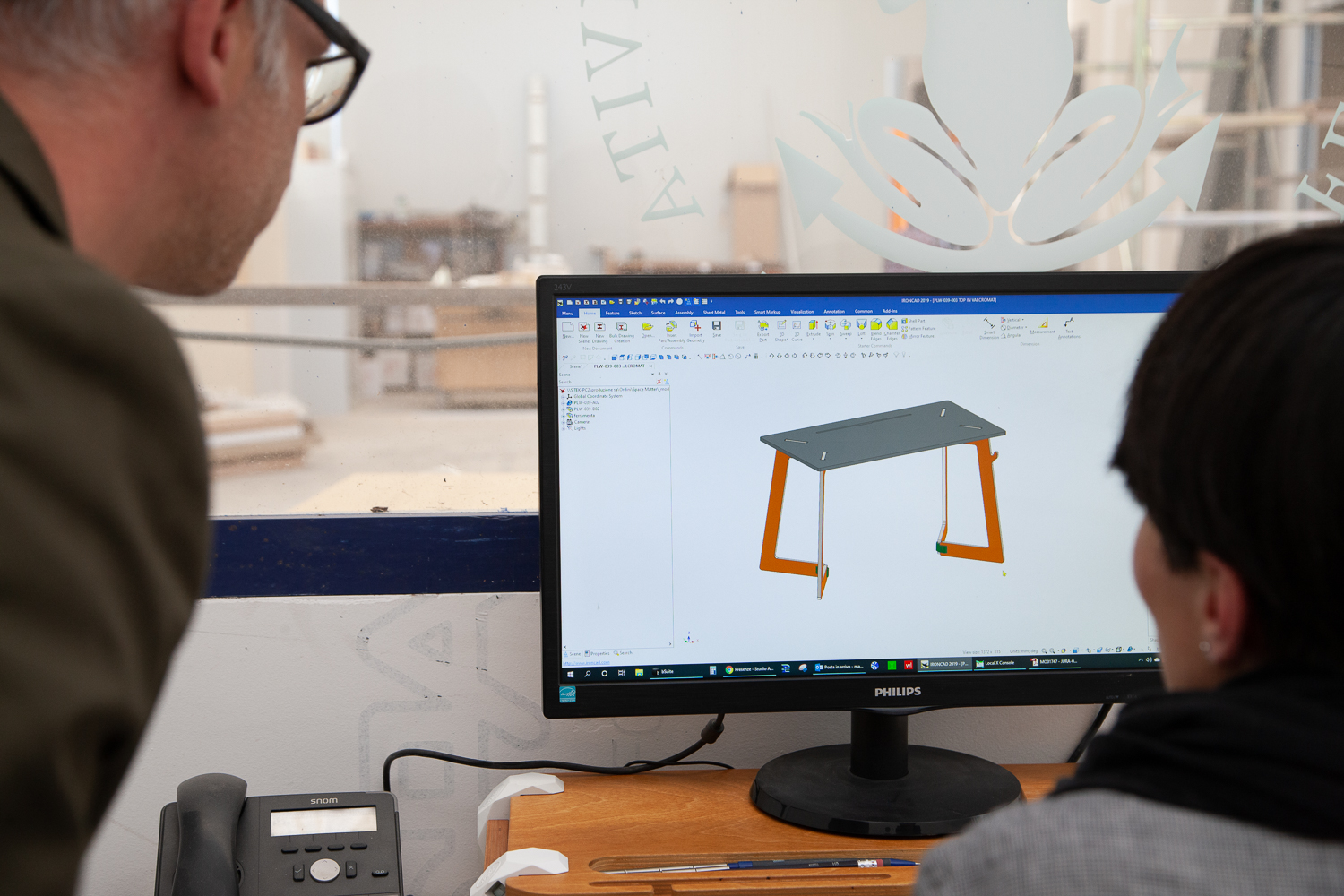

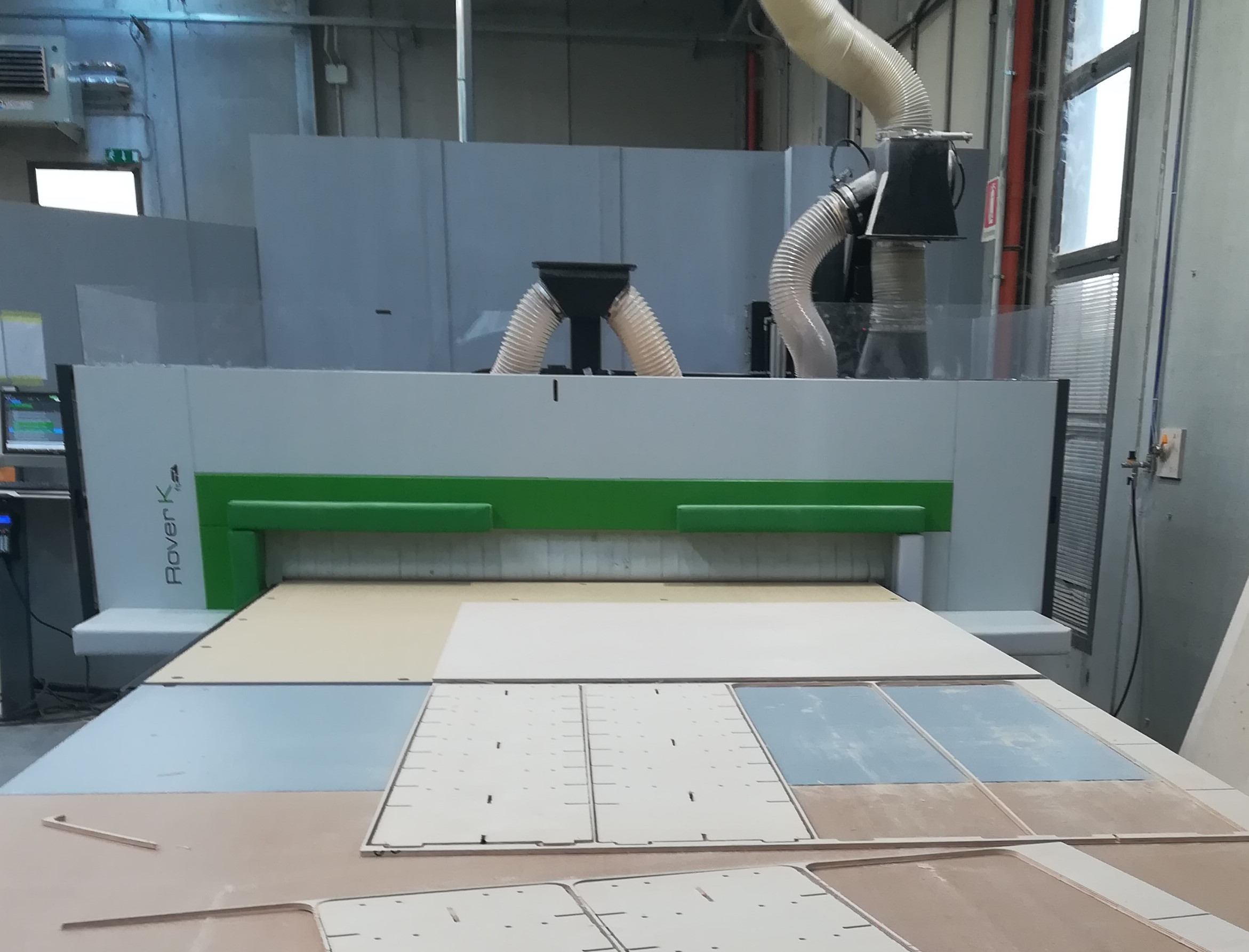

Esposit deals with the design and production of easy, light, and sustainable furniture thanks to the interlocking technique. By following this philosophy, Esposit designs and produces wood displays, Store forniture, fair/congress set-up and modular furniture.